As you can see, we have achieved a very nice fit.

Started April 21, 2007

The Cargo Doors are skinned with .032 aluminum sheet (2024 T3). The door skins must be bent or ceased slightly in a couple of locations so that when looking along the side of the airplane fuselage, the stringer shapes on the fuselage side are continued onto the cargo door. Done properly, the cargo doors blend so well that they almost disappear when closed.

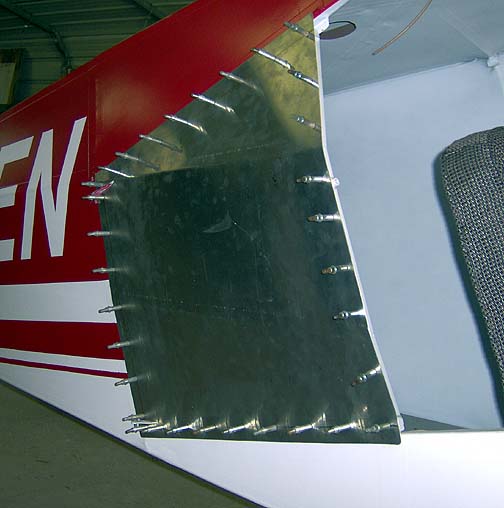

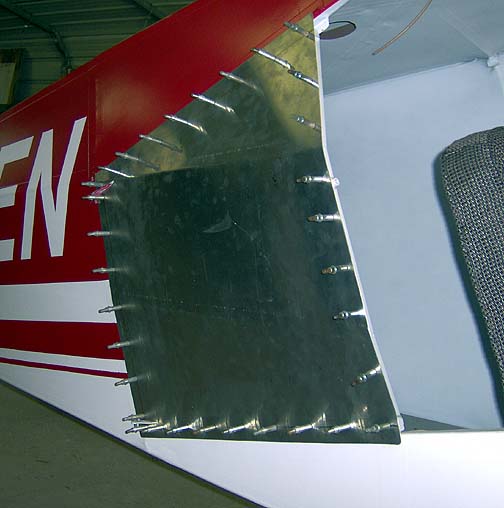

Here is the aft cargo door showing the creases. Next, all of the edges were

cut to create a 1/4" overlap of the door opening in the fuselage. The

edges were smoothed and the corners rounded with a file. Here is the aft

cargo door attached to the fuselage:

As you can see, we have achieved a very nice fit.

So far so good, now its time to skin the forward cargo door. The forward cargo door has a window, but we sill start by just skinning the door with one piece of aluminum. Once the skin is properly fitted, the window opening will be cut.

Again the doorframe was placed in the fuselage and location of the creases

were marked as a reference. On the forward cargo door, the crease is

made at the aft end only. You can see it in this picture:

This partial crease was done by leaving one side of the brake up and clamping

down the other side before making the bend.

Next, the window opening will be cut.

The aluminum window frame made last year, was fitted on the inside of the forward cargo door. This window frame was positioned to exactly match the positioning of the window on the pilots side of the fuselage. One properly positioned, the frame was drilled and clecoed to the cargo door skin.

The inside opening of the window frame was then traced onto the cargo door

skin and the hole for the window was cut:

After some filing, and smoothing here is the window opening in the cargo

door:

Cargo Door Skins

Completed: May 1, 2006

Total Time: 16 hours

Click here to go to the Final Assembly page

Click here to go to the Home page