June 15, 2009

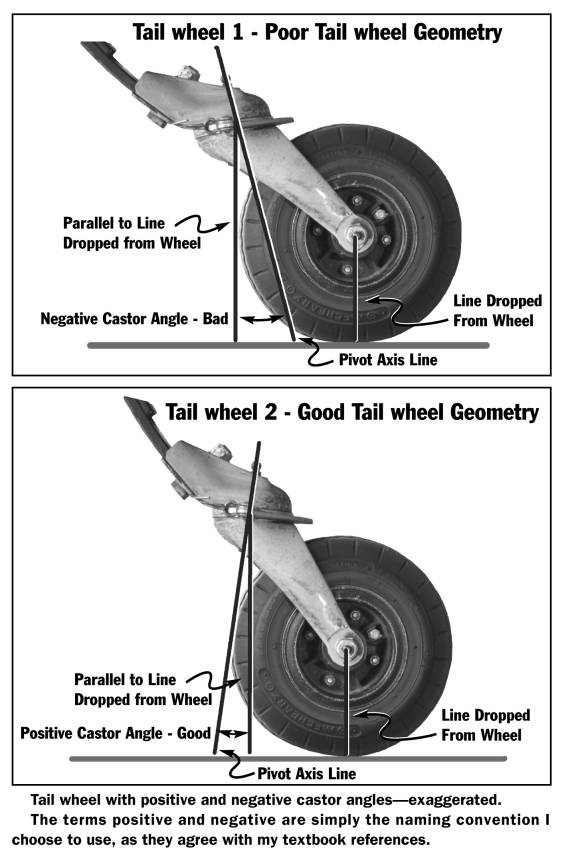

In the past few weeks, N57EN has developed a tailwheel shimmy that can be

felt when landing on asphalt runways. I had known for sometime that

the tailwheel assembly king pin (the pivot point for steering) was not where

it should be(it had a negative castor angle), but since I had no shimmy,

I left it alone. According to my research, the pivot point of the tailwheel

assembly (the king pin) should be vertical, 90 degrees to the ground when

the aircraft is fully loaded. Here is a diagram showing a Scott Tailwheel

but the basic principle is the same:

So when viewed for the side, the king pin should be either vertical or just slightly tilted toward the front of the airplane on the bottom (back at the top).

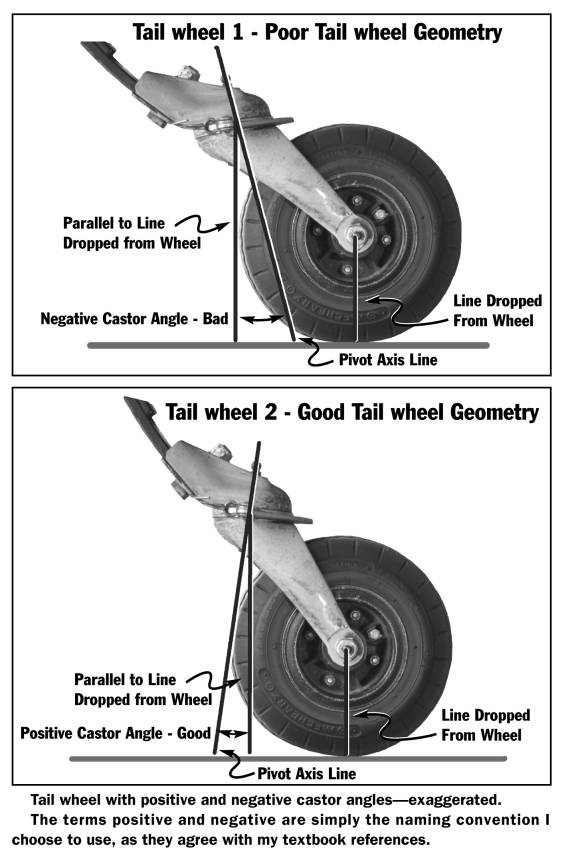

In my case, the top of the king pin was tilted back at the bottom (forward

at the top) without any load on the airplane (and only 1/2 full fuel

tanks):

The line represents the king pin. You can imagine how much this negative

castor angle increases when I put a load at aft CG on it and the tailspring

straightens out some more.

When I first bought the tailspring it was arched too much and I used a 30 ton press to un-arch it some. It appears that I un-arched it too much. Now after several hundred landings, some of them dropped in from 2 feet off the runway, the tailspring has settled and de-arched some more. So it's time to remove everything, and re-arch the tailspring.

After disassembly, I took the tailspring over to my friend Mickey's house

and we traced the spring shape onto a piece of cardboard for a starting reference

point:

The 3 leaf springs were then taped together with the holes lined up and placed

into a 30 ton hydraulic press as shown here:

After several presses and checking, we achieved an increase of about 1/2"

to the spring arch:

The springs had never been painted, so I took this opportunity to go ahead and sand them and painted them flat black with some rust inhibiting paint.

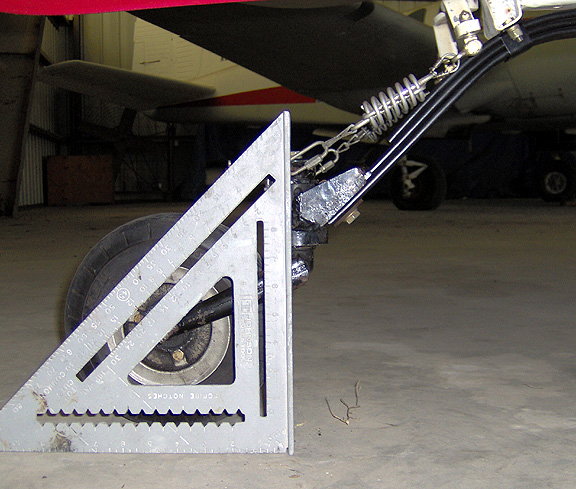

The tailspring and tailwheel assembly were re-installed on the airplane and

the angle was re-checked. It appears that the amount of re-arching is pretty

close but still not quite enough to create positive castor. Now, with

no load on the aircraft, the king pin is vertical (perpendicular to the floor).

I guess I could use just a bit more but want to test fly it before

bending any

further:

This means that with a load, the tailspring will straighten slightly with

a net result of the king pin being slightly tilted giving me negative

castor.

I went ahead and flew the airplane over to a nearby asphalt runway and did a series of landings. The shimmy seems to be gone now. I will have to see if the shimmy returns when I load some people and cargo onboard and get it closer to gross weight and aft CG. If so, I can either shim the tailspring at the fuselage attachment point pad or re-arch the tailspring a bit more. If not, I'll leave it as is.