This exposes everything firewall forward, allowing a complete inspection of the engine and all components.

May 9th - May 25th, 2009

The end of May 2009 marks one year since N57EN received it's Airworthiness

Certificate from the FAA . The AW certificate was accompanied by a

set of Operating Restrictions, which state that N57EN must undergo a condition

inspection annually. At this point, N57EN has 90 hours on it and has

been flying for almost one year, so I feel its time for a thorough inspection

anyway (even if it wasn't required). The inspection can be performed either

by the builder (with a repairman's certificate) or an A&P mechanic. Being

the builder and having the repairman's certificate for N57EN, I will be

performing the inspection myself.

My checklist for the annual condition inspection can be downloaded by clicking here.

The key to doing a really good inspection is to take it in stages, completing

each stage before moving on to the next. For instance, don't inspect

anything while removing the inspection panels and cowling (step 1); just

work on getting the plane opened up for inspection. Then as you conduct

your inspection, don't stop and fix anything found until you have completed

the inspection (step 2); just make a list of deficiencies and keep inspecting.

During step 3, you'll go back and do the actual work to fix anything found

in step 2. Finally, button it all up again and go flying. Here are

the suggested steps to complete in order:

1. Remove the spinner, cowling, all inspection panels, gap

fairings and wing tips (but don't inspect anything yet).

2. Inspect everything and make a list as you go of what needs

to be fixed (but don't fix anything yet).

3. Fix any discrepancies you found during the inspection and

check it off on your list.

4. Put it all back together and go test fly it.

To do a thorough inspection, several components need to be removed. This

includes the entire engine cowling (top and bottom) including the nose bowl

as well as the spinner and prop:

This exposes everything firewall forward, allowing a complete inspection

of the engine and all components.

The wingtips were then removed, as well as all of the wing inspection hole

covers:

The wing root fairings and fuel tank covers were also removed:

Next, the inspection hole covers at the tail were removed:

The bottom skin between the landing gear legs was removed so I could inspect

everything in there and get at the gascolator:

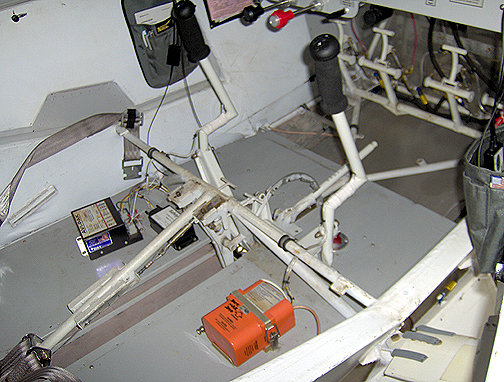

The front seats were removed, as well as the tunnel covers and front

floorboard:

Normally, the front floorboard doesn't need to be removed for the inspection,

but I wanted to install a little insulation on the top of the tunnel skin.

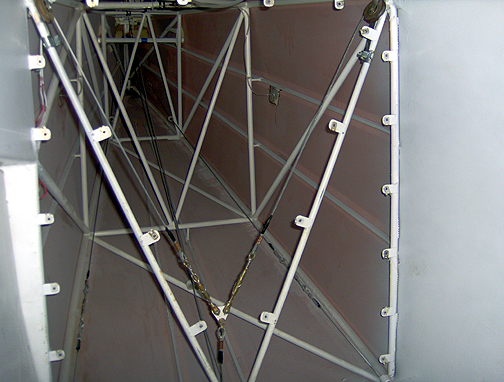

Finally, the rear baggage bulkhead skin was removed to allow full access

to the aft fuselage:

Click here to go to Annual Condition Inspection page

2