I decided to build the tailwheel myself as I have access to a lathe and it seams like a good project for a beginner machinist like me.

I started by making the most complex part of the assembly, the main body. It starts with a piece of 2.5" round steel bar. Here is the steel bar being cut on the 14" cutoff saw:

The piece was then installed in the lathe and machined.

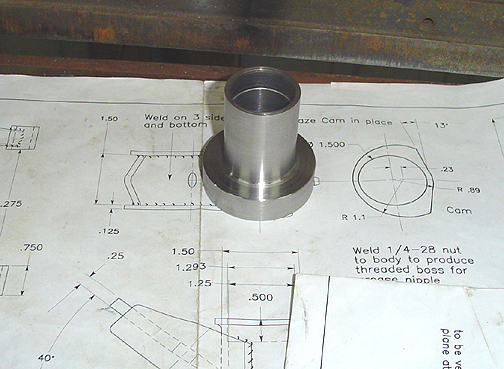

Here is the completed part ready for welding the spring mounting plates on:

The tail spring plate and side plates were fitted and welded on the piece at the correct angle as shown in the plans. Once that was done, the piece was chucked up in the lathe again and the opening for the ball bearing was final cut to size. The bearing should be a light press fit so its snug in the opening. Here is the bearing installed:

The top end of the housing was machined to accept a brass bushing. The brass bushing was made from solid brass stock. Here is the brass bushing in the housing:

You can also see that a 1/4 -24 nut was brazed on the housing for a grease fitting. After installing the nut, a hole was drilled at the center to allow the grease to flow through. The cam on the top of the housing was made from .125 steel plate and welded on top. This was all done before final machining of the inside of the housing. Its best to have all the welding complete before final machining of the inside surfaces.

Click here to go to Tailwheel page 2

Click here to go to the Fuselage Index page

Click here to go to the Home page