December 1, 2004

Well I went and did it now. Just when I thought that I was finished with the tail parts, I got to looking at the rudder and realized that something just wasn't right with the Rudder Horn.

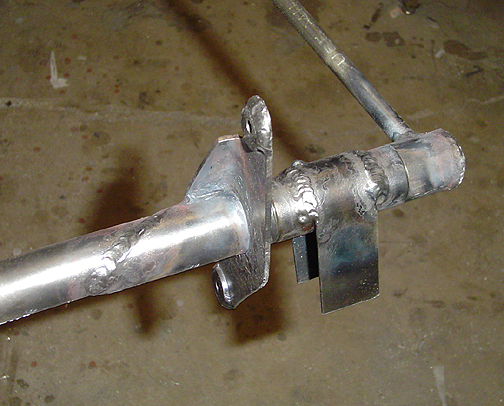

In the above picture you are looking at the front side and the rudder (see the trailing edge tube at the top of the picture?). The problem? The rudder horn is welded on backwards. Yep, that's right - BACKWARDS. The flat tabs in the back are supposed to be in the front and will later act as rudder stops. The part sticking out in front of the rudder spar is supposed to be in the back and will definitely have an interference problem with the tail post.

Well after much discussion on the Bearhawk group site and a couple of calls to Bob, I have a solution.

My first thought was to carefully cut at the weld where the 1" rudder horn tube meets the 7/8" rudder spar (30 degree angle). Then, grind and sand the weld smooth, spin the rudder horn around the right way then weld it back on to the spar. The problem is that I don't want to cut into the spar and weaken it. I can't imagine how I would be able to cut fine enough to not hit the spar tube.

Then after some discussion with the group and Bob, I decided to just leave the 1" rudder horn tube in place and cut only the ears and remaining .090 plate part of the rudder horn off. I could then grind and sand it smooth, then make a new rudder horn plate and weld it back on. That way I would never touch the spar.

First I had to cut away the old rudder horn. I used my air die grinder with a cut off wheel for that:

Then the weld had to be sanded down until it was flush with the 1" tube portion of the rudder horn. This is where I like to say that when you are given lemons, make lemonade. I needed something to sand the weld smooth - AHA!! Here I had an excellent excuse to buy a new tool! So I went down and got a new 90 degree air die grinder and some sanding wheels:

Gee I'm feeling better already. This baby rocks!! I was able to smooth off the weld in short order and it left a nice smooth finish on the 1" rudder horn tube.

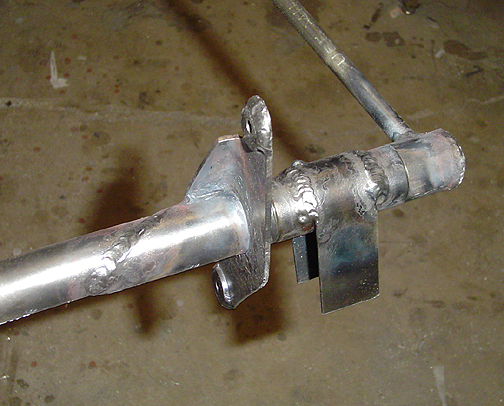

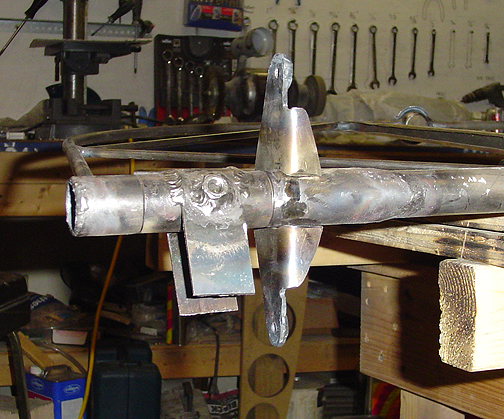

Next I made the .090 rudder horn plate again. To get it on to the 1" tube, I cut the notch in the rudder horn plate 7/8" wide so it would slip over the rudder spar, then slid it down onto the rudder horn tube. Here is the new rudder horn plate in place and ready to be welded:

After re-checking about 10 times that I had the correct orientation, the spacing from the hinge was correct, it was square and it was perpendicular to the rudder trailing edge and ribs, the Rudder horn was welded in place.

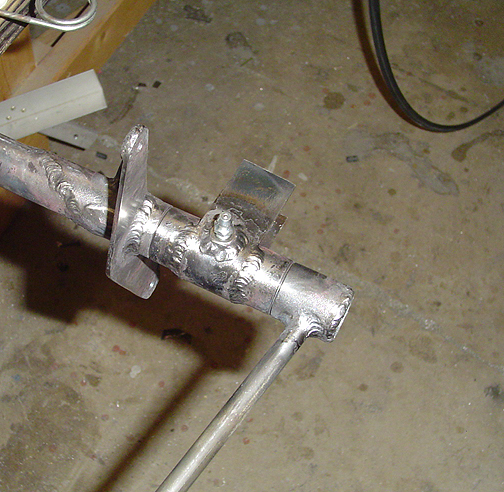

Well here it is, now facing the right direction:

That's one thing I like about the steel portion of this project. Most boo boo's can be fixed with cutting and welding. This Rudder Horn mistake is now fixed AND I got a new tool out of the deal. I added 4 hours on to the build time of the rudder for this little mishap. Time to move on. . .