The plans call for tail wires made from 1/4" 4130 N rod. The rod is threaded on each end and then turned down to a smaller diameter between the threaded areas to relieve stress at the point where the threads begin.

I chose to go with the stainless steel, streamline flying wires available from Steen Aero Lab. These are fairly pricey but have rolled threads and are cut to a streamline shape full length. All of the research I've done on aerodynamic drag indicates that round rods and tubes in the wind create an incredible amount of drag. Also is the fact that Bob Barrows recommends buying the flying wires instead of machining your own unless you are very experienced with how to cut threads in a way that will not create a stress point in the rod (where the threads begin on the rod). Since these are fairly critical, I chose to purchase the flying wires instead of attempting to make my own.

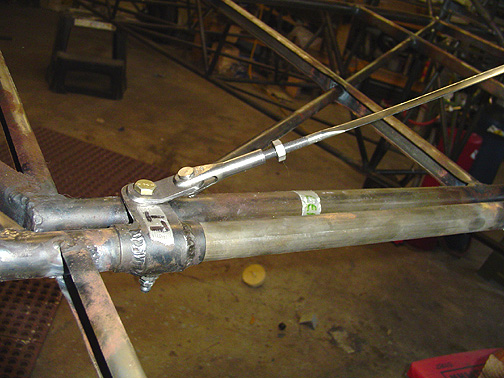

Here is a picture of one of the flying wires hooked to the mounting link

at the outer elevator

hinge:

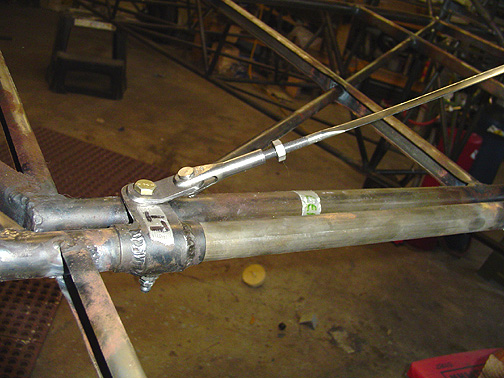

Here it is at the top rudder hinge:

Here are to top flying wires mounted to the Horizontal Stab and Rudder:

Note the level is used to assure proper alignment of the horizontal stabilizer.

The same thing was done for the flying wires on the bottom side of the stabilizer. The flying wires are threaded with left hand threads on one end and right hand threads on the other end. What this allows you to do is simply turn the wire to tighten or loosen. The top wires were tightened until both horizontal stabilizers were level. Then the bottom wires were tightened. Too much tension on one side and the rudder will bind. Get even tension on both sides while keeping both stabilizers level. It should be tight enough that the stabilizers cannot move without moving the whole fuselage.

Click here to go to Mounting the Horizontal Stabilizers page 4